2 Common Types Of Steering Mechanisms

The steering mechanism plays a crucial role in assisting the driver to control and direct the vehicle as per their intentions. Certainly, it stands as one of the most remarkable innovations in the automobile industry, giving the capability for effortless turning of a car in various directions. Did you know there are mainly two types of steering racks? This article will discuss two common types of steering mechanisms and how the steering system works.

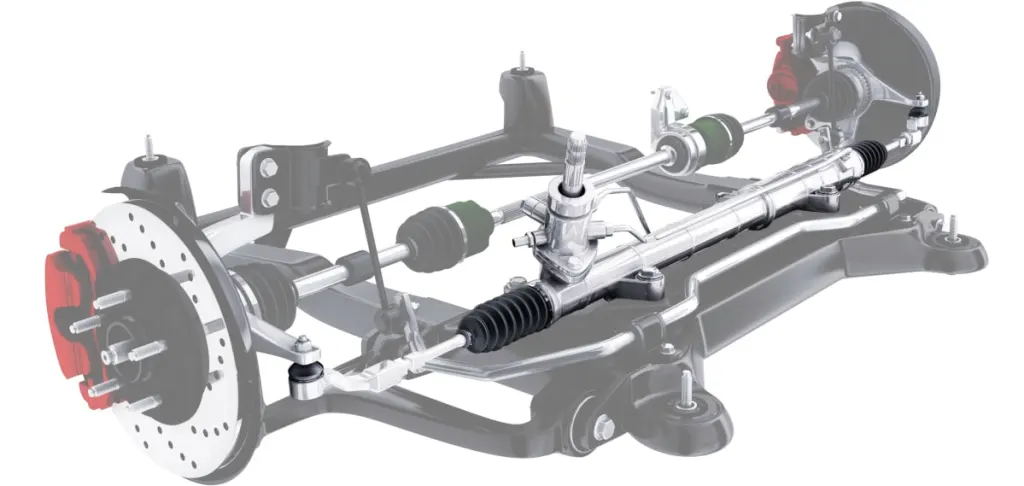

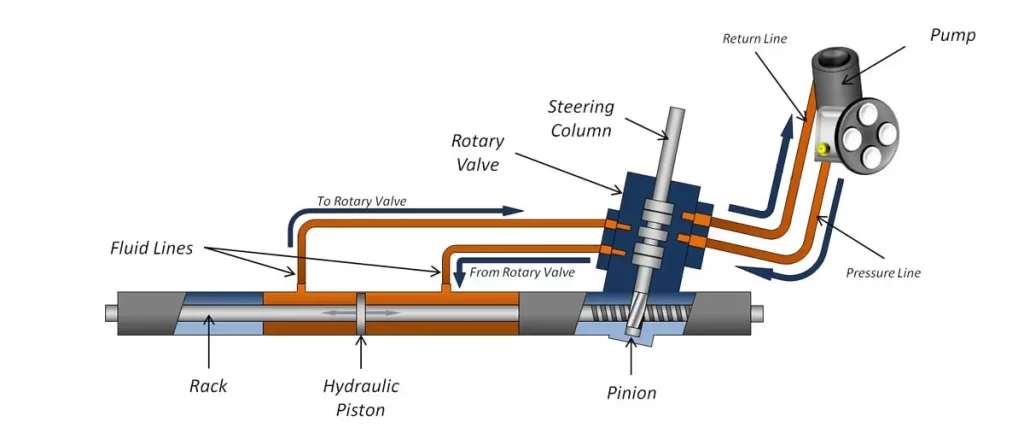

Hydraulic Power Steering Rack

A hydraulic power steering rack, also known as a power steering rack or simply a steering rack, is a crucial component in modern power steering systems used in vehicles. Its primary function is to assist the driver in turning the wheels of the vehicle with less effort, especially at low speeds and during parking maneuvers.

When the driver turns the steering wheel, it causes the steering column to rotate. This movement is translated into linear motion by the steering rack, which pushes or pulls the tie rods connected to the wheels. The control valve regulates the flow of pressurized hydraulic fluid to either side of the steering rack’s piston. This creates a power-assisted force, helping the driver to turn the wheels with reduced effort.

As a result, the hydraulic power steering rack provides a smoother and more responsive steering experience, especially in heavier vehicles or at low speeds, making driving more comfortable and convenient.

Electric Power Steering Rack

Electric Power Steering (EPS) is a type of power steering system used in modern vehicles to assist the driver in turning the wheels with less effort. Unlike traditional hydraulic power steering systems, which use fluid pressure to assist steering, EPS systems rely on an electric motor.

The key component of an EPS system is the Electric Power Steering Rack. The steering rack is a mechanical component responsible for translating the rotational motion of the steering wheel into lateral movement of the wheels, allowing the vehicle to turn left or right.

Electrical Power Steering Rack

When the driver turns the steering wheel, the sensors detect the input, and the ECU commands the electric motor to provide the necessary assistance to turn the wheels. The level of assistance can vary depending on the driving situation, such as at low speeds (parking) or high speeds (highway driving).

The advantages of Electric Power Steering include improved fuel efficiency compared to hydraulic systems (as the electric motor consumes power only when needed), the ability to integrate with other safety and driver-assistance systems, and the potential for adjusting steering feel and responsiveness.

Overall, Electric Power Steering systems have become increasingly popular in the automotive industry due to their efficiency, versatility, and potential for integration with advanced driving technologies.

In simple terms, power steering makes it easier to turn the steering wheel in a vehicle. Without the assistance provided by the electric or hydraulic system, the steering wheel would feel heavy and hard to turn. If you’ve experienced the power steering failing in your car, you’ll understand that navigating corners, parking, and maneuvering at low speeds become a strenuous upper body workout.

In conclusion, hydraulic power steering racks are based on hydraulic fluid pressure and require more maintenance, while electric power steering racks use an electric motor and have less maintenance needs. Electric power steering also offers more control over the steering feel and contributes to better fuel efficiency. The choice between the two systems often depends on a vehicle manufacturer’s design preferences, cost considerations, and desired driving characteristics. In recent years, electric power steering has become more popular due to its advantages in fuel efficiency and adjustability.